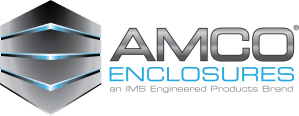

SEISMIC ZN4 ELECTRONIC PACKAGING CABINET

Seismic Server Cabinet

Titan Packaging ZN4 racks for seismic server cabinets have been engineered, tested and achieved the GR-63-CORE certification. This is key for Mission Critical electronic packaging equipment that experiences exposure to seismic events and ground vibrations. Instead of experiencing those risks, these seismic server cabinets will keep your equipment free from damage whenever an earthquake occurs. You also won’t have to worry about your packaging equipment falling on any of your employees during an earthquake. Instead of watching your incident rate increase, Titan cabinets will help your facility maintain worker safety and boost your company’s reputation in the industry. Plus, the cabinets will allow your facility to remain efficient by avoiding disruptions to your business. Instead of experiencing slowdowns that can occur when equipment experiences damage during earthquakes, your company will be able to work as normal and keep clients satisfied—thanks to the cabinets. These will also help you avoid the time-consuming process of shopping for new machines or having damaged ones repaired. That will enhance your reputation for reliability in your industry. AMCO Enclosures offers Titan seismic server cabinets in both open or closed configurations. We also offer ZN4 racks with a full line of accessories that will grow the capabilities of your rack. Titan seismic server cabinets truly offer peace of mind for your data center.

Sizes: Heights of 35RU, 40RU and 45RU, Width – 24” and Depths of 25.5”, 30” and 36″

Certified Seismic Load Rating:

1,200 lbs.

Features:

- Full line of accessories for Electronics Packaging

- Enhanced base, additional diagonal struts, gussets and seam welding

- Top and base are open for cable management options

- 4 weld studs for Grounding

- Available in 11 standard colors

- Custom branding available

- Custom sizes and accessories are also available

- Contact AMCO directly for test results

- Durable powder coat finish

- ISO9001 Certified

- 10-Year Warranty

- Designed and manufactured in the USA

Mounting Channels:

Mounting Channels

All mounting channels have a clear zinc finish, and feature your choice of either M6 (square) or #10-32 (tapped) holes with individually numbered RUs for each rack unit. Individually numbered rack units make equipment installation fast and easy, minimizing downtime.

MCX mounting channels feature standard 19″ mounting in 24″ overall frame widths. MCW reducer channels feature 19″ mounting in a 29″ overall frame width.

Panels:

Side Panels

Side panels have been designed for use as baffle panels or to finish off the sides of the enclosure. With this design, two frames can be joined together while separating the internal environment within each frame. Side panels mount within the side perimeters of the rack for a flush design aesthetic.

Side Panel Features

- Side panels come with one keyed lock (36″ depth side panel has two locks), keeping panels secure

- Side panel latches provide easy on/off mechanism (latches not included on 12RU-24RU panel sizes)

- Side panels can be mounted in place between multiple-bays

- Side panels can be bolted from within the rack for permanent mounting

Top Panels

Top panels provide options to address today’s cooling and cabling requirements. They also provide an additional level of security as they are bolted directly to the top of the rack.

Each panel features multiple cable egress ports, which include dust covers to close off the top when the ports are not in use. This excludes the solid without cable egress ports top panel.

Doors:

Face and Flush Doors

Doors are available as either face or flush mount. Face mount doors mount to the enclosure’s exterior surface. Flush mount doors mount flush with the frame’s exterior surface.

Door Features

- Concealed hinges on face mount doors offer easy on/off release

- Doors can be used as either left-hand or right-hand

- Vented doors feature a 77% open airflow pattern, exceeding major equipment vendor requirements

- Swing handles with keyed locks

- Combination swing handle locks optional

- Locks can be ordered keyed alike or separately (keyed separately option quoted upon request)

- Doors are available in solid, polycarbonate, vented and louvered

Shelves and Drawers:

Shelves

Heavy Duty Adjustable Shelves

Heavy Duty Shelves are 1.75″H (1RU) and adjust to fit 19″ width panel openings, with depths from 17″ up to 40″. They are available in solid or vented models and are load-rated to support up to 300 lbs. Shelves mount to the front and rear of the mounting channels.

Heavy Duty Retractable Shelves

Shelves mount to the front and rear of the mounting channels. They slide out for easy access to equipment.

Light Duty Shelf

Light Duty shelves mount to the front of the mounting channel. The shelves are 19″ wide,18″ deep and available in the following heights: 1RU, 2RU, 3RU, 4RU and 5RU. They are capable of supporting components up to 50 lbs., with the exception of the 1RU shelf that holds 15 lbs.

Drawers

Heavy duty drawers have a 150 lb. load rating and feature adjustable slides that mount to the side flanges of the mounting channels. The drawer’s formed front panel includes an aluminum handle with the same color powder coat finish as the drawer, as well as a keyed lock.

Cable Management:

Lacing Bars

Give your system the support it needs with lacing bars from AMCO. Lacing bars mount horizontally and assist in cable tie-down and provide strain relief for cabling. Both the “C” and straight models have punched slots to accept cable ties. They are offered in straight, “C” style 2″, 4″, and 6″ depths, and round 2” depth. Lacing bars are available in packs of 5 and feature a durable black powder coat finish.

Lacing Strips

AMCO has an extensive variety of flexible cable management accessories to manage your cabling requirements. Our lacing strips are 5” wide and come in the same corresponding RU heights as the racks. They are perfect for vertical cable bundle tie-downs or mounting power strips. They feature a multi-punched hole pattern for M6 hardware mounting or cable ties.

AMCO adjustable lacing strips are available in 1RU and 2RU heights and depths of either 14”- 21” or 25”-37”. These lacing strips mount front-to-rear, or in the panel-opening space to tie down cabling. Both the 5” lacing strips and the adjustable lacing strips feature a multi-punched hole pattern for M6 hardware mounting or cable ties. All lacing strips feature a durable black powder coat finish.

Cooling:

Fan Stacks

Fan Stacks – Ultra Quiet-Fans with Front Exhaust

AMCO fan stacks cool hot spots in your rack. This 1RU fan tray mounts to specific hot zones in your rack and features two ultra-quiet fans (27db) that turn on from 83-85º. The unit is 115V/15-amp, delivers 120CFM of cooling and is available in depths of 8” and 14”. Unit includes a 5-ft. power cord and durable black powder coat finish.

Fan Panels

Fan Panels- Ultra Quiet Fans with Display

Fan panels come standard with static or adjustable digital temperature management. Static panels feature an 83-85 º alarm set point, ensuring that your security components will operate at peak performance. Fan panels are 115V/15-amp and include ultra-quiet fans (27db). Adjustable thermostat fan panels come standard with a digital display. All fan panels include a 5-ft. power cord and a durable black powder coat finish.

Power:

Basic Power

12-outlet 115V/15-amp power strip for vertical mount or 6-outlet 115V/15-amp for horizontal mount is available. All power strips include a 10 ft. cord. Other power strips are available. Contact your local sales representative for more information.

Surge Protection Power

Surge protection power strips are ideal for smaller environments that don’t have protective surge suppression at the facility level, or just when additional protection is needed. Parallel circuitry keeps our Surge protection power strips working even if a surge or spike disables surge suppression.

Non-Surge Protection Power

Non-Surge protection power strips are ideal for facilities already equipped with surge protection.

Metered Non-Surge Protection Power

Metered non-surge protection power strips are ideal for facilities already equipped with surge protection.

Other Accessories:

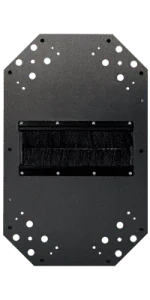

Base Plate

Base plates are manufactured from 14ga. CRS and provide a safe and secure, heavy duty surface at the bottom of the enclosure. They are internally mounted to the enclosure for ease of assembly and access. Base plates provide protection from outside elements and are available as a solid panel or with dual brush strips that provide easy cable and power entry/exit into the rack without affecting the enclosure’s internal environment.

Open area of dual brush strip section is 16″ L x 5″ W for larger power cords and cable bundles. Base plates feature two additional #12-24 grounding studs that are .625″ long, located on the internal side flange of the base plate.

Power

AMCO Enclosures understands the importance of power in today Rack environment. We offer a select grouping of standard vertical and horizontal 15A and 20A power strips for typical day to day designs. We can also provide metered, monitored, switched PDU’s and environmental units – in expanded 30A -120A models. A variety of cord lengths are available as well as other options.

Features

- Flexible designs

- Variety of cord lengths

- Made in the USA

Enclosure Panels

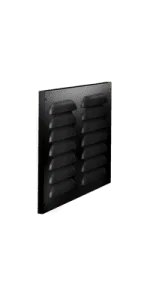

Full-Length Enclosure Panels

Full-length enclosure panels can be modified to incorporate cutouts, punched holes or other custom finishing that support the entire system’s design. Enclosure panels are available in both solid or louvered models and are formed.

Enclosure Panels

Enclosure panels are used to block out specific RUs for current and future deployment, or to provide a finished look for your overall system. All enclosure panels are formed.

EPS/EPL Series Enclosure Panels on this page cannot be used in conjunction with FLUSH mounted doors on a Titan frame. If panels are required please see Blanking(FLAT) Panel Accessory.

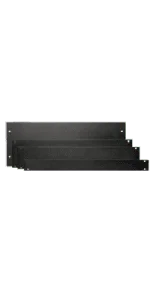

Blanking Panels

Solid blanking panels fill out empty rack space and help direct air where needed. Vented blanking panels allow heat produced by components to dissipate while covering any blank space between components. Formed blanking panels are aluminum and also available individually or in kits.

Note: For 29″ width, please contact your sales representative.

Chassis Guides

Chassis guides have a 2″ H x 2″ W profile and are fully adjustable from 25” through 36″. The flanges support component-mounted hardware in a minimal profile. Chassis guides support 125 lbs.

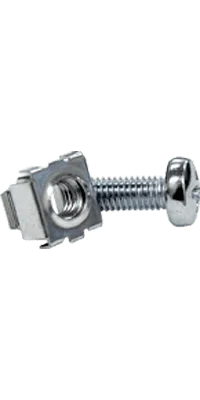

Hardware Kits

Each rack ships with 50 ea. Dzus M6 inserts and screws to make mounting hardware/components easy to install. Additional mounting hardware is available for equipment mounting:

Square Hole Mounting Hardware Kits

- HKM6-25 or 50: M6 hardware includes 25 or 50 screws for equipment mounting

- HKDZ-25 or 50: M6 Metric DZUS includes 25 or 50 easy inserts and M6 clear chromate screws.

#10-32 Tapped Hole Mounting Hardware Kits

- T441- (25) #10-32 X 1/2 black phillips pan head screw w/washer

- HK500- (500) #10-32 x 1/2 black phillips pan head w/washer

Bus Bar

Vertical busbars are used to ground your valuable equipment within the rack. Busbars are copper with a ½” W x 2″ D profile. They feature #10-32 tapped holes and are available for all standard frame heights.

Frame joining kit (8 pieces) included with each cabinet.

Frame joining kit (8 pieces) included with each cabinet.